Why Poly Foam

Most concrete raising jobs will take between one to two (2-4) hours—start to finish—and your concrete will be ready for use immediately upon completion!

Step 1) Injection holes are strategically drilled around the areas where the concrete is sunken and requires lifting.

Step 2) Once everything is prepped and the hose and materials are in place, the polyurethane foam is injected through the holes which fills the space underneath the concrete slab, using the concrete slab itself to drive the foam into the crevices, thereby lifting the concrete back to its original, correct level.

Step 3) Upon completion of leveling the concrete, the injection hole(s) are filled discretely with new cement, allowing you to use your surface immediately.

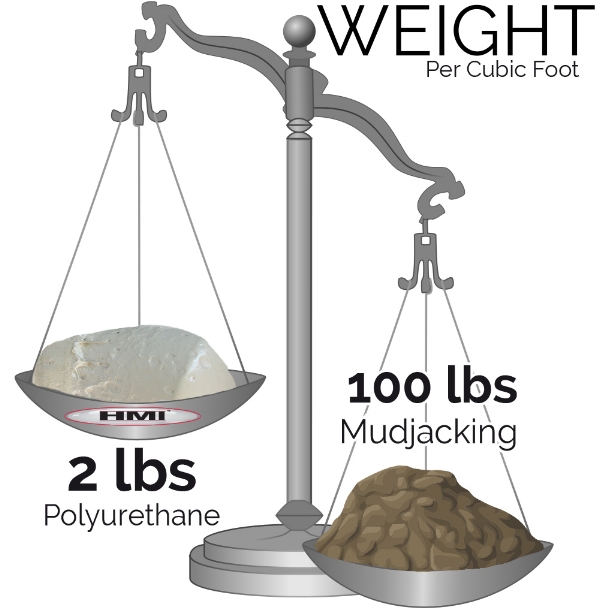

Summary: Polyurethane Concrete Raising uses a foam material that is injected under the slab. When the components of this material are mixed, a reaction causes the material to expand. This expanded foam fills any voids beneath the slab and raises concrete. This material will never lose density, is permanent and weighs only about 2 lbs. per cubic foot.

Cost Effective: Concrete raising is typically about half the cost of replacing the same concrete. Ultimately, the cost of raising or stabilizing concrete is a direct reflection of how much leveling material the project will require.

Cost Effective: Concrete raising is typically about half the cost of replacing the same concrete. Ultimately, the cost of raising or stabilizing concrete is a direct reflection of how much leveling material the project will require.